Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Food Production Line Metal Detector For Food

-

≥1/piece

USD 6,999.00

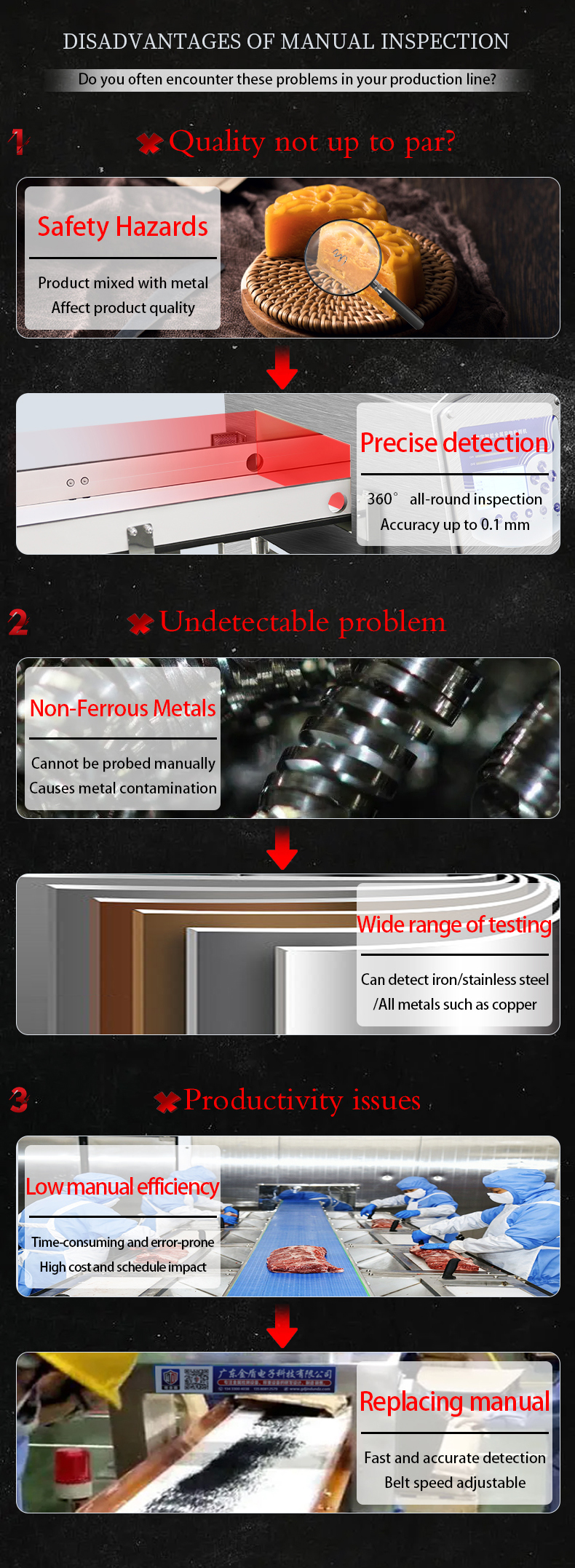

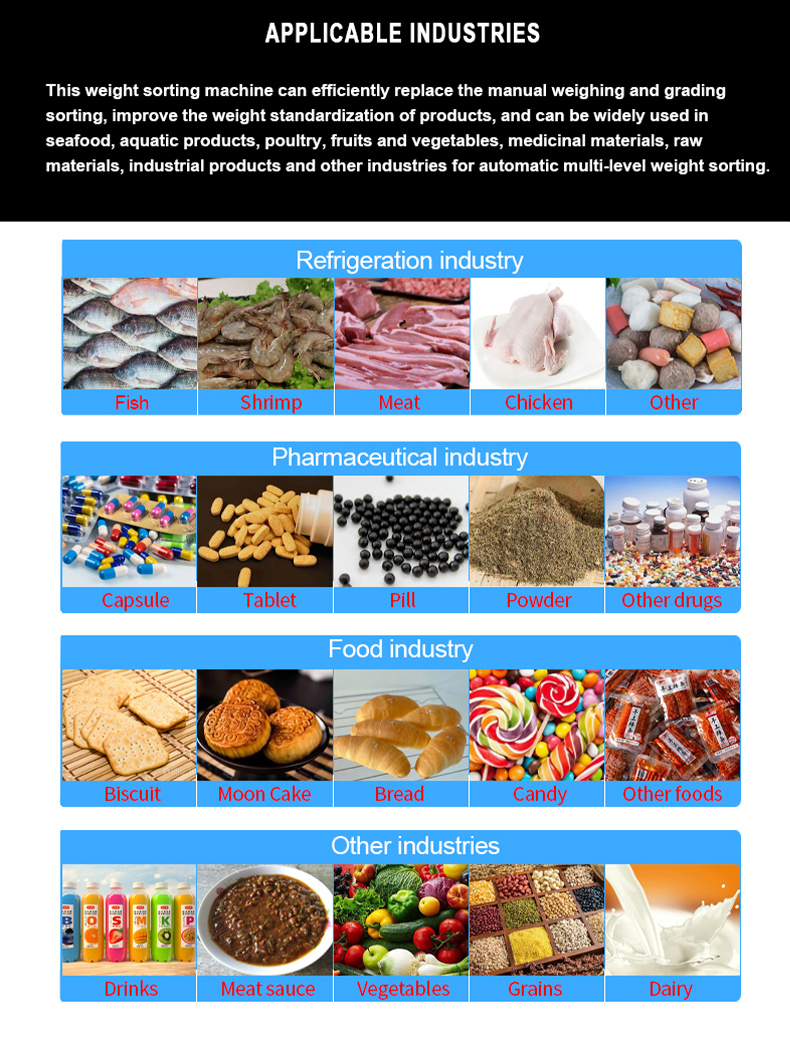

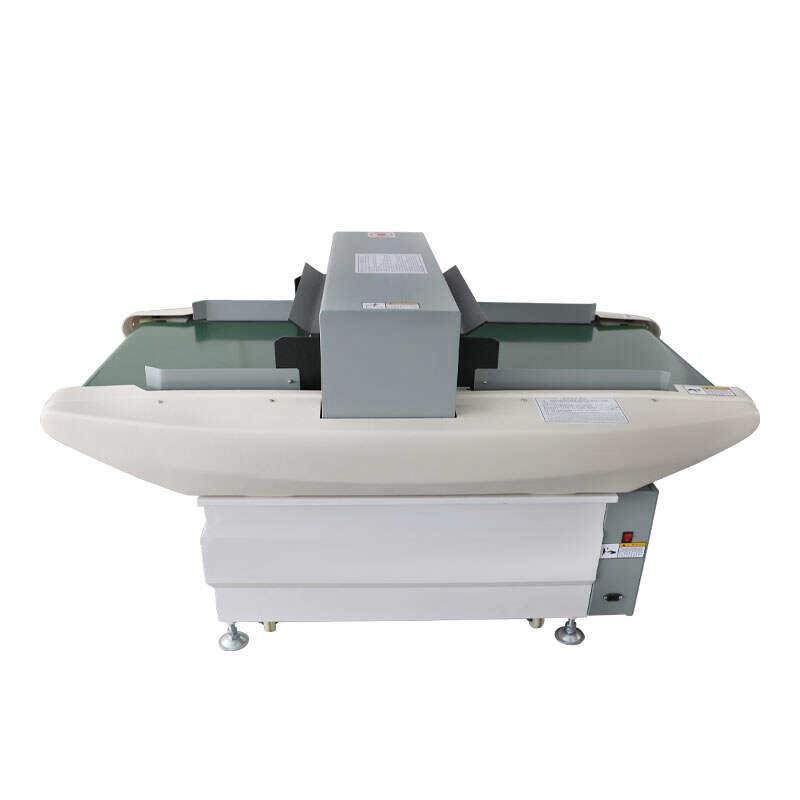

The conveyor metal detector for food production lines is an essential component of food processing systems, designed to ensure product safety and quality control. It is a highly advanced technology tailored specifically for the food industry to detect metal contaminants in food products during the production process. This detector helps maintain compliance with stringent food safety regulations and standards, ultimately safeguarding consumer health and brand reputation.

Description of Product

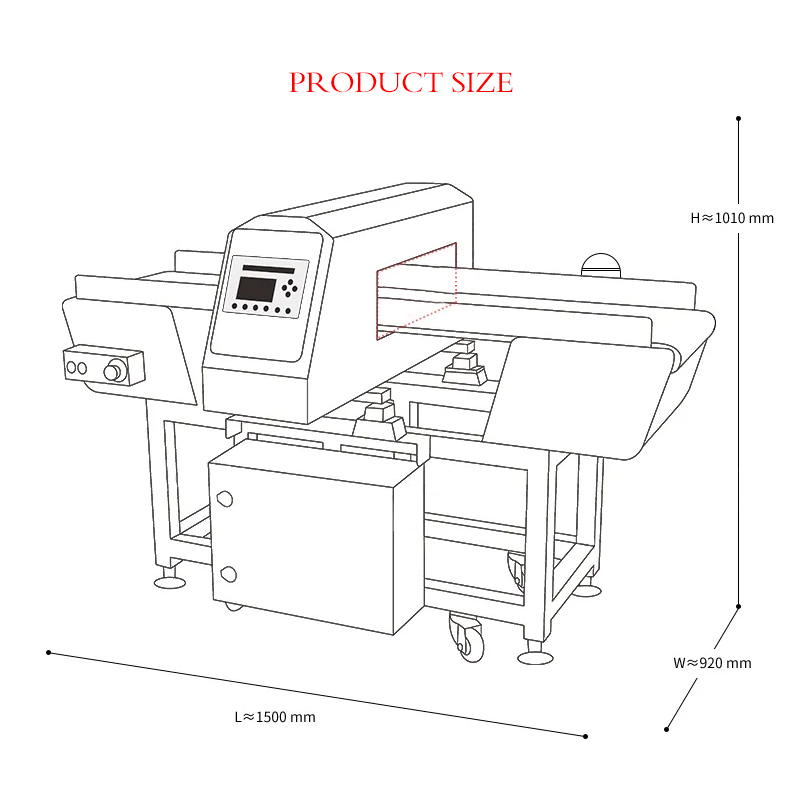

The Food Production Line Metal Detector is integrated seamlessly into conveyor systems, allowing for efficient and continuous inspection of food products as they move along the production line. Utilizing advanced electromagnetic technology, it can accurately identify and reject metal contaminants such as ferrous, non-ferrous, and stainless steel particles as small as a few millimeters in size. Its robust construction and precise detection capabilities make it a vital tool for ensuring the purity and safety of food products.

Features of Product

1. High Sensitivity: capable of detecting even minute metal contaminants, ensuring thorough inspection of food products.

2. Customizable Settings: Adjustable sensitivity levels and detection parameters to suit varying product types and production environments.

3. Integration Flexibility: Easily integrates into existing conveyor systems without disrupting workflow or production efficiency.

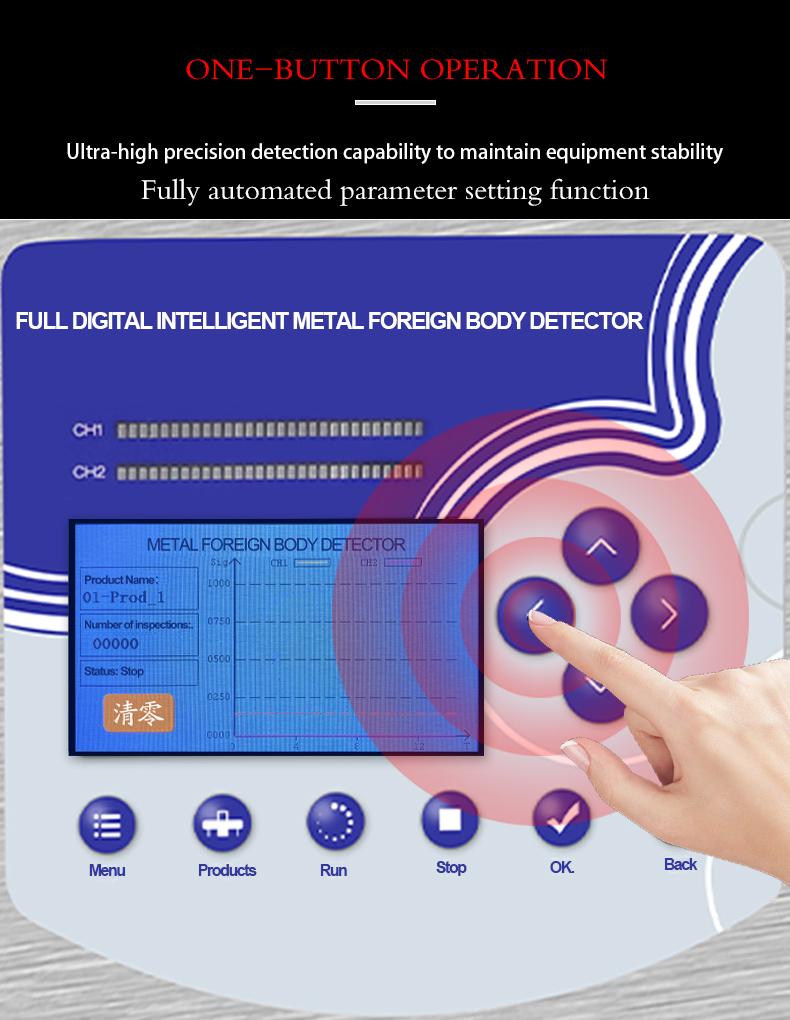

4. User-Friendly Interface: intuitive controls and user interface for simplified operation and monitoring.

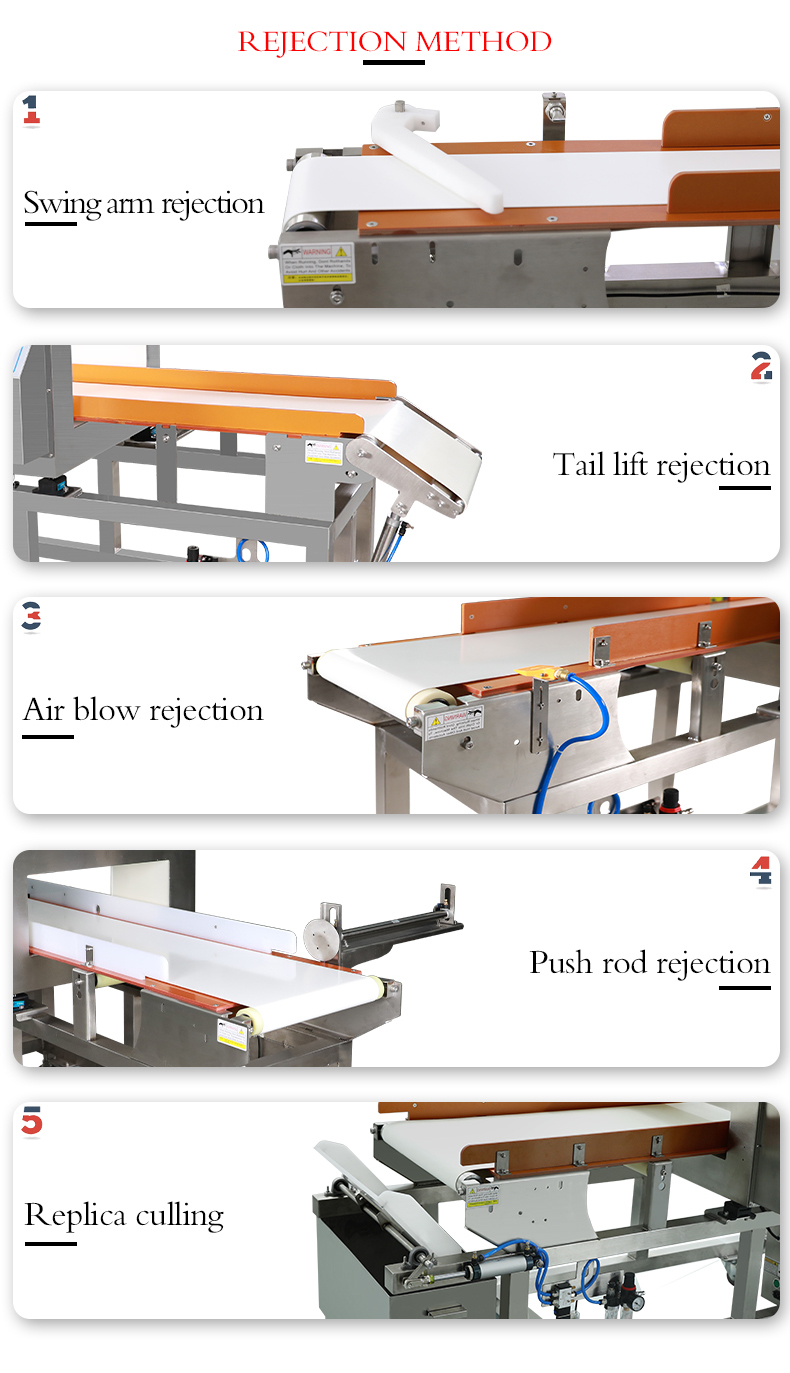

5. Automatic Rejection: Automatically removes contaminated products from the production line, minimizing waste and ensuring product integrity.

6. Durable Construction: Built to withstand the rigors of industrial food processing environments, ensuring long-term reliability and performance.

7. Compliance Assurance: Meets and exceeds industry standards and regulations for food safety, providing peace of mind to manufacturers and consumers alike.

Advantages and Benefits of Product

1. Enhanced Product Safety: Reduces the risk of contamination-related food recalls, protecting consumer health and brand reputation.

2. Cost Savings: Minimizes product waste by swiftly identifying and removing contaminated items from the production line, reducing financial losses.

3. Compliance Assurance: Helps manufacturers meet regulatory requirements and standards, avoiding penalties and legal liabilities.

4. Improved Efficiency: Streamlines the quality control process, allowing for continuous inspection without causing delays or interruptions in production.

5. Brand Protection: Demonstrates a commitment to food safety and quality, fostering trust and loyalty among consumers.

6. Peace of Mind: Provides reassurance to both manufacturers and consumers that products undergo rigorous inspection for metal contaminants, ensuring their safety and integrity.